the custom-designed classic

VESTAMID® L – polyamide 12

Evonik is one of the world's largest producers of polyamide 12 (PA 12), which it markets as VESTAMID® L. We benefit here from backward-integrated production: From butadiene as the starting material Evonik produces laurolactam, the monomer for PA12, in a multi-stage process. We are currently building an additional complete production complex, which will increase our capacity by more than 50%. Additionally, Evonik is offering its customers a further type of sustainable polyamide 12 molding compounds. Selected commercial VESTAMID® products can now be manufactured using sustainable energy at Evonik’s Marl Chemical Park in Germany.

The concentration of amide groups is lowest in polyamide 12 and determines its special properties.

Customized TO THE REQUIREMENTS

Evonik's VESTAMID® L compounds comprise a large number of different products tailored precisely to the requirements of processors and end users.

The properties of semicrystalline polyamides are determined by the concentration of amide groups in the macromolecule. This is lower in PA 12 than in all other commercially available polyamides, which accounts for its special properties:

- Minimal water absorption: molded parts show almost no dimensional changes with variation in atmospheric humidity.

- Extraordinarily high impact resistance and Charpy notched impact strength, even well below freezing point

- Good to excellent resistance to greases, oils, fuels, hydraulic fluids, and many solvents as well as to salt solutions and other chemicals

- Excellent resistance to stress cracking, even for metal parts encapsulated by injection molding or embedded into the plastic

- Excellent abrasion resistance

- Low dry sliding friction coefficient as compared with steel, polybutylene terephthalate, polyacetal, and other materials

- Noise and vibration damping properties

- Excellent resistance to fatigue caused by frequent load change

- Easy processability

Thanks to these properties, the applications of VESTAMID® L range from sophisticated line systems for motor vehicles, through large-volume pipes as are used in crude oil production, core insulation in the cable industry, and catheters in medical technology, to precision injection-molded parts like impellers and control-valve housings in machine and equipment manufacture.

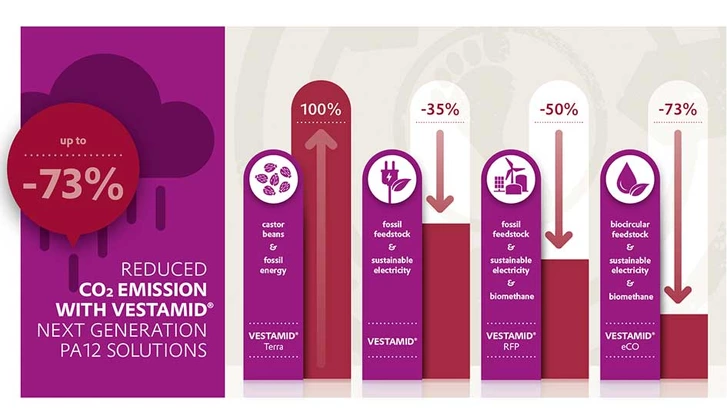

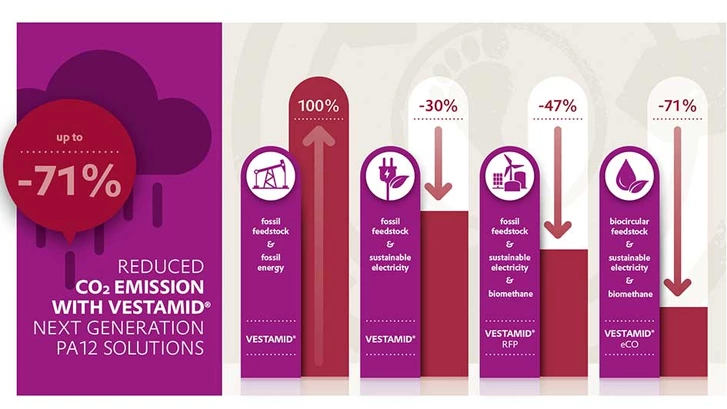

VESTAMID® RFP stands for "reduced footprint"

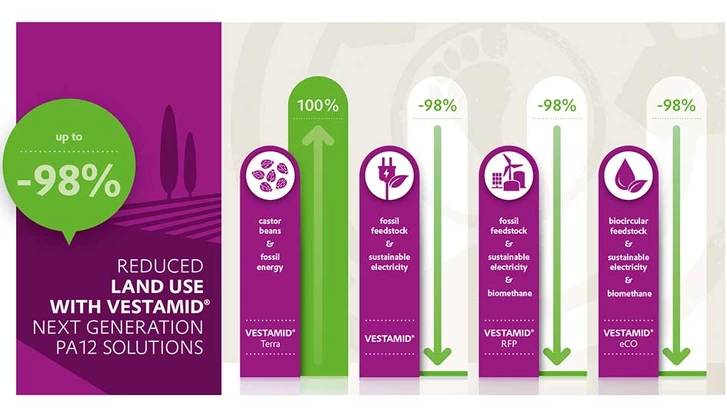

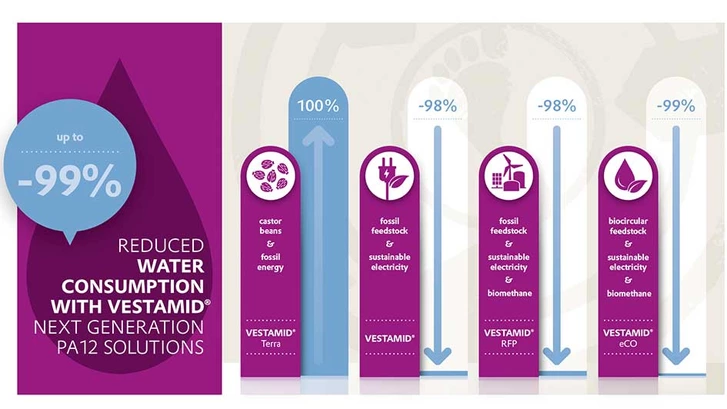

Evonik has been producing polyamide 12 at the Marl Chemical Park in North Rhine-Westphalia for more than 50 years and uses the electricity and steam produced there by its own state-of-the-art and efficient combined heat and power plants. By using biomethane generated from waste in these plants, emissions of the climate gas carbon dioxide for VESTAMID® RFP are reduced by an average of 40 percent, while water consumption and land use remain almost the same.

BETTER LIFE CYCLE ASSESSMENT ALSO COMPARED TO BIO-BASED POLYAMIDE

Since 2009, Evonik has also marketed VESTAMID® Terra molding compounds, which are based on monomers obtained from castor oil. In comparison, VESTAMID® RFP shows a significantly improved eco-balance: the carbon footprint is reduced by 40 percent, while water consumption and land use are more than 99 percent lower.

Find the right polymer!

We offer a broad portfolio of products tailored to different requirements.

- unfilled polyamide 12 compounds

- plasticized polyamide 12 compounds

- filled, reinforced, and flame-resistant polyamide 12 compounds, and

- permanently antistatic and electrically conducting polyamide 12 compounds

Compare the properties in our plastics database