Sustainability

Improving the sustainability of our High Performance Polymers

Sustainability is a central element in Evonik’s goal to make life better for present and future generations. Every day, we work towards goals that include our three most important sustainability topics: Decreasing our footprint, increasing our handprint and driving circularity.

Since October 2023, Evonik has been harnessing sustainable electricity to produce its VESTAMID® compounds. With our strong production network in Marl, we have decreased the carbon footprint of an average PA12 compound by 30%.

We additionally offer products that incorporate waste-based biomethane and sustainably sourced raw materials, using a mass balanced approach. These products have up to 70% less carbon footprint than other products, yet have the same exact quality, properties and performance. Customers can fully benefit from these more sustainable solutions while preserving their processes and existing manufacturing-chain certifications.

Up to 70 percent less CO2 in the production of VESTAMID® eCO, compared to conventional VESTAMID®

Life cycle assessments (LCAs) are available for most of our products. You can find them on our Plastics-database.

Certified footprint-assessments

Transparency is the key to sustainability decision-making. We provide externally certified life cycle assessments so our customers can make fact-based decisions. This allows customers to improve the sustainability of their processes in a well-documented, data-based approach, and be better prepared for future requirements. Our data has been evaluated and certified by independent experts from TÜV Rheinland. Life cycle assessments (LCAs) are already available for more than 100 of our molding compounds.

Visit our plastics database for more information or contact us directly.

VESTAMID® Compounds

All of our standard VESTAMID® compounds are produced with sustainable electricity. This reduces our emissions by 30 percent for a standard compound as compared to our production in 2023.

VESTAMID® RFP

Our VESTAMID® RFP (“Reduced footprint”) product line reflects Evonik’s companywide goal of providing high-performing, sustainable solutions to our customers. At our cogeneration plants in Marl, we use biomethane recovered from waste to generate steam and heat, and we also use sustainable electricity – in total, this lowers the CO2 emissions of our VESTAMID® RFP by up to 50 percent. The increased sustainability of our manufacturing process has no effect on quality: VESTAMID® RFP products have the exact same high-quality properties as our standard VESTAMID® range.

VESTAMID® eCO

At Evonik, we’re committed to making a more sustainable chemical industry. One way we do this is by saving fossil resources through the use of alternative raw materials. Our eCO products are manufactured with renewable energy and raw materials procured from sustainable sources in a mass-balance approach.

We offer raw materials for eCO products from three sources: 1) bio-based raw materials such as vegetable oils; 2) bio-circular raw materials such as residual materials from forestry and agriculture, or from food scraps; and 3) recyclable raw materials such as old tires and used plastics.

VESTAMID® TERRA

Since 2009, Evonik has offered molding compounds made from plant-based starting materials. Our VESTAMID® Terra products are made from monomers obtained from castor oil.

OUR CONTRIBUTION TO A SUSTAINABLE FUTURE

As a globally active company, Evonik is serious about its opportunity to contribute to a better future. We have integrated sustainability into our commitment of “Leading Beyond Chemistry.” Currently, sustainable product solutions account for 43 percent of our total sales. We want to increase the handprint our products leave. By 2030, we aim to increase these “Next Generation Solutions” even further, so they form more than 50 percent of all of our sales.

Evonik is also committed to reducing absolute greenhouse gas emissions with a 25 percent reduction in scope 1 and 2 emissions and an 11 percent reduction in scope 3 emissions by 2030.

WE MAKE THE RAW MATERIALS FOR TOMORROW’S SUSTAINABLE PRODUCTS

Through continuous research and product development, Evonik is continually adapting its portfolio to the needs of an evolving world.

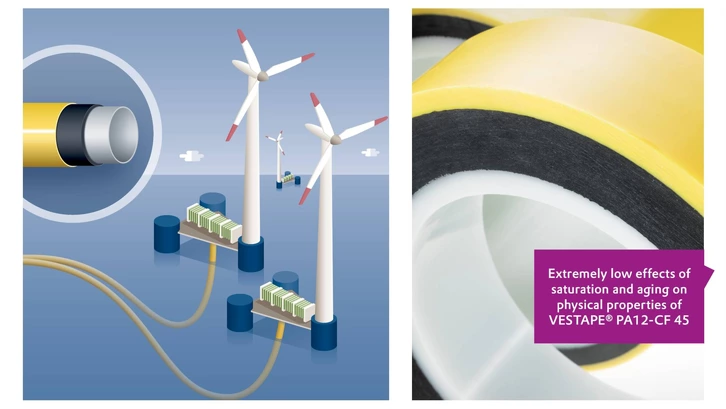

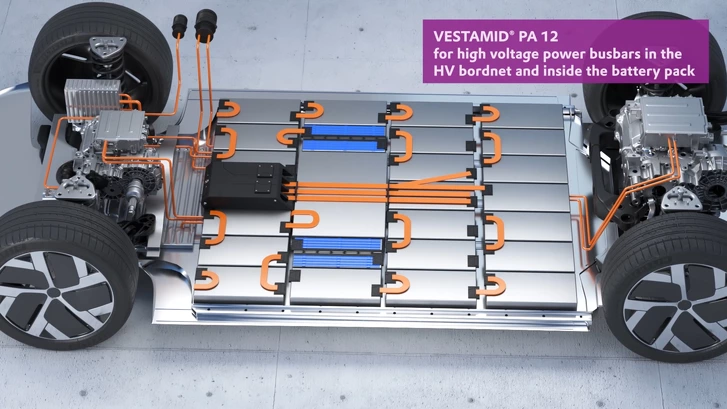

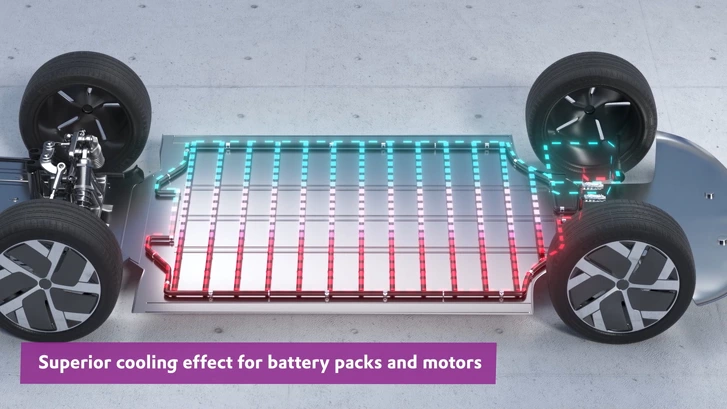

Our VESTAMID® products are currently the world’s most widely used polyamide 12 for automotive wiring systems. The demand for VESTAMID® continues to as the world shifts to more electrified modes of transport. VESTAMID® is a versatile product – along with wiring systems, it is an ideal material for use in busbars and other electric-vehicle battery and charging systems.

In the future, VESTAMID® products can also be used in pipelines to transport hydrogen, which is a clean fuel that has only water as a byproduct when properly consumed, or in linings for tanks to store CO2, a greenhouse gas than can be recovered and later used in many industrial processes, including the creation of renewable bio-methane-based alternative fuels.

SUPPORTING TECHNOLOGIES THAT IMPROVE EFFICIENCY AND REDUCE WASTE

We also make INFINAM® products especially designed for 3D printing technologies. On-demand printing is practical, sustainable and resource-saving, and cuts down on overproduction, unnecessary inventory and material waste.

DRIVING FORWARD A CIRCULAR ECONOMY

To reduce waste, we look at developing a sustainable, circular economy on a global scale. An effective circular economy requires collaborative efforts across the full value chain. Evonik contributes to this by pooling together all its circular plastics activities across the globe, in an concerted effort to develop new ways to collect plastic waste and recycle it back into high-quality raw materials.

Let us drive PA12 circularity further with you.