Reducing our footprint

Leading the way to more sustainably produced vestamid compounds

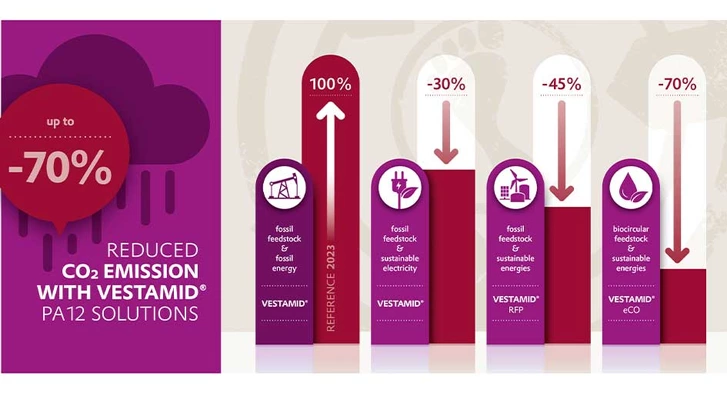

We decrease the carbon footprint of our highly integrated production sites for long chain polyamides, by using sustainable electricity to produce all VESTAMID® compounds. In total, this commitment to sustainable electricity will reduce our carbon emissions for VESTAMID® compounds by 30% compared to our benchmark product.

The switch to sustainably produced electricity is in line with the strategic transformation towards a Next Generation Evonik. Our Company´s commitment to Science based targets initiative covers the ambitious targets of reducing scope 1 and 2 emissions by 25 percent until 2030.

more Transparent

While we work towards more resource-efficient production and sustainable products, we also want to be as transparent as possible with our customers. As such, we have prepared comprehensive life cycle assessments (LCAs) for the majority of our VESTAMID® compounds and had these assessments externally certified by TUV Rheinland. These LCA certificates are now available on request. Besides information on the carbon footprint, these assessments also cover relevant impact categories, such as water and land use.

MOre Choice

As a complement to the overall transition to using more renewable energy, we go a step further with VESTAMID® RFP products. Using the green power and further harnessing biomethane from waste to generate steam and heat, we can further reduce CO2 emissions by an additional 15% from our products today. In addition to its lower carbon footprint, our VESTAMID® RFP products retain the exact same high-quality properties of our standard VESTAMID® product range.

BIOMETHANE from evonik’s sepuran® green Membranes

Biomethane is a renewable natural gas that can be recovered by sustainably recycling organic waste with a high energy potential. This is made possible by Evonik’s SEPURAN® Green membranes, which can separate crude biogas into 99% pure biomethane, using a patent protected 3-membrane-stage process. Through this circular economy approach, the resulting biomethane can be further processed into an alternative fuel that burns cleaner than traditional fossil-fuels.