customized

VESTAMID® Injection Molded

Whether it's a miniature part, a K&K composite or a highly filled fitting - certain VESTAMID® compounds are specially designed for injection molding. They can be processed on commercially available injection molding machines to produce high-quality end products.

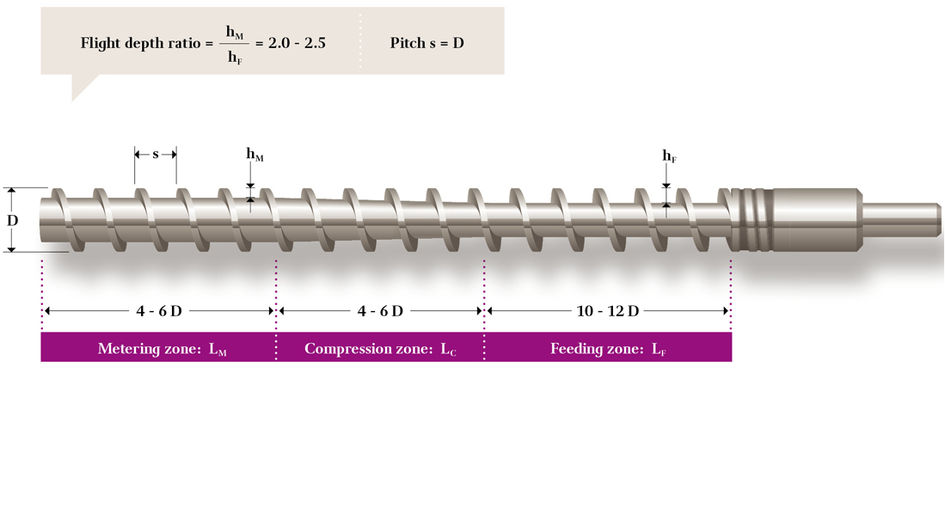

Design of a three-zone screw

Typial values for VESTAMID® compounds in injection molding (*for 30 m screws)

|

LF |

LC |

LM |

hF* |

hM* |

hF/hM |

|

10 D |

5 D |

5 D |

5 mm |

2 mm |

2.5 |

- Three zone screw with a length between 18 and 22 D

- Depth flight ratio shall be > 2

- Minimum flight depth: 2 mm in the metering zone, and 4 mm in the feeding zone

- Screw and barrel diameter should be in the magnitude that a metering stroke between 1 D and 3 D is realizable

- Optimal in the range of 3-12 m/min

- Larger speeds (e.g. > 18 m/min) can be applied, but might lead to problems in processing.

- In general free-flow nozzles, for low viscous resins (e.g., VESTAMID L1670, VESTAMID L1723) externally operated shut-off nozzles (e.g. needle valve nozzle) are recommended

- Bore of nozzle should be app. 0.5 to 1.0 mm smaller than the gate

Clearance between back flow valve and cylinder shall be ≤ 0.02 mm

Light contamination (e.g. cleaning due to changing of resin)

- Prepare the mixture of high viscous PP and purging resin PLEXIFIX with a mixing ratio of 2:1.

- Increase the temperature settings of heating zones by 30 to 40 K but not above 300 °C.

- Plasticise the mixture with a long metering stroke and high dynamic pressure and discharge with high speed into the atmospheric environment.

- Flush the plasticating unit with the new resin until no purging mixture is contained in the melt.

Persistent contamination can mostly be removed only by mechanical cleaning of screw, cylinder, back-flow valve etc. Sometimes a cleaning of the cylinder can be avoided by using special purging material such as RAPID PURGE, SUPERNOVA or ASACLEAN.

Guide number for maximal pressure in cavity with VESTAMID® resins: 200 to 600 bar.

- All established types of sprues, runners and gates are possible.

- Diameter or thickness of pin, submarine and film gates shall be ≥ 0.6 mm

Externally heated hot runners with open sprue nozzle is recommended, nozzle diameter shall be ≥ 0.6 mm

Venting slots in mold parting surface: 0.01 to 0.03 mm deep, 4 to 5 mm wide

Suitable steels: 1.2767 (X45NiCrMo4), 1.2379 (X155CrVMo121), 1.2312 (40CrMnMo58) and 1.2343 (X38CrMo V 51)

Use of a pressure sensor for the cavity pressure is recommended to facilitate the carefully setting of change-over point.

- Usually a demolding agent is not necessary.

- Decrease of mold temperature very often eases demolding.

- Suitable coatings of mold surface are Ni-PPTFE, and TiAlOx.

- Mold temperatures for PA12 and PA612 grades 30 - 100 °C, for PEBA grades 15 to 40 °C, for PA610, PA 1010, and PA 1012: 60 – 100°C.

- In general temperature of nozzle and heating zone close to nozzle to be set on melt temperature; in case of free-flow nozzles setting of nozzle temperature 10 K below desired melt temperature might be advantageous for non reinforced resins.

- Decreasing temperature profile in the heating zones towards hopper in steps of 10 K is recommended

- Cooling of feeding zone should be 40 - 80°C.

Special temperature settings are listed with the respective product in our palstics database

- For short production breaks (e.g., up to 1 hour): discharge of the plasticting unit, moving of screw to ultimate front position and decreasing temperature setting at heating zones down to 150°C

- For long production breaks: flushing of the plasticating unit with high viscous PP or PMMA, discharge of the plasticating unit, moving of screw in ultimate front position, switch off of cylinder heating. Remove resin left in the hopper and store in moisture proof packaging

Two-component injection molding

Composite parts consisting of a hard component and an elastomer have proven their worth wherever rubber parts have to be permanently fastened or fixed. Traditionally, the hard component of composite parts is made of metal. In order to reduce weight - especially in vehicles - more and more metal components are being replaced by suitable plastic parts wherever possible. With the patented plastic-rubber composite process, specially developed molding compounds can be used in two-component injection molding to produce strong and durable bonds to suitable rubber compounds without special pretreatment and without adhesion promoters.